The final quad structure design has been recently finalized! The quad structure is the truss work which spans the space between the 4 rotors and supports the pilot in the middle.

Upon starting construction of Atlas, it was determined that a structure composed of simple, single span beams would be able to support regular flight loads. This was not a very efficient structure but it demonstrated that a structure could be constructed at a feasible weight.

Initial Atlas tent structure made with a triangulated single beam.

It was immediately evident that a truss structure would be required to reduce the weight of the structure by allowing the material failure of the structure to be closer to the buckling failure of the long unsupported beams. It was my design task to analyze the forces on the structure in order to design the optimal structure for the helicopter, making it robust even under worst case flight conditions.

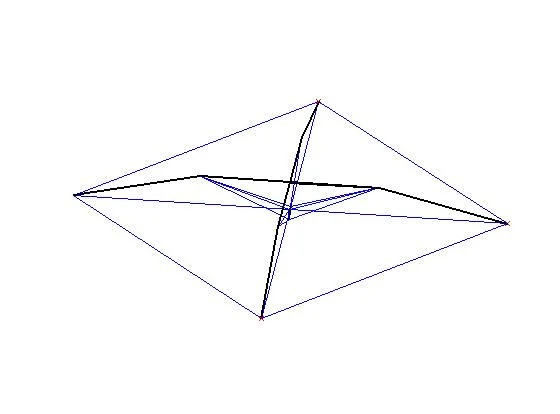

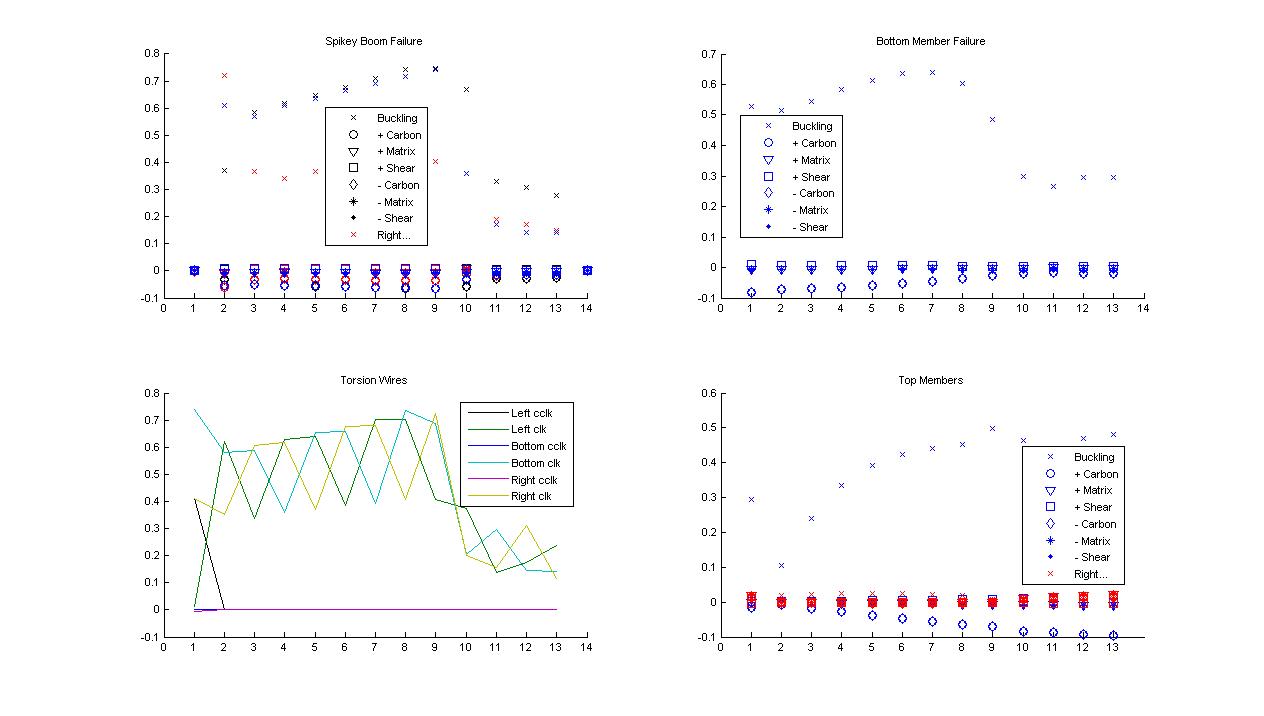

I first wrote a custom finite element analysis (FEM) code with 12 degrees of freedom to determine the forces on every part of the structure under a given loading condition. An image of the displaced helicopter under worst case flight loads can be seen in the first image below. From the internal forces given by the FEM, a failure analysis could be conducted. Some graphs from the failure analysis for one quarter of the structure can been seen in the second image below. Considered in the analysis was the failure of wires, buckling of members as well as several modes of material failure of each layer of carbon which is applied to every tube. The final configuration of the structure was designed to satisfy a total of 2615 failure modes!

Displacement plot by FEM code under worst case flight conditions.

Failure analysis code output.

After developing the FEM to study the forces on the structure, various configurations where analyzed before a final concept was decided on:

Final Configuration of the quad structure.

Upon arriving on a concept for the quad structure, the final configuration could be defined by several design variables. The blue members seen in the image above are wires and the black members are carbon fibre tubes. There are many difficulties to designing a wire braced structure such as wire pre-tension and a wire’s inability to take compressive loads, all of which I had to account for in the FEM code.

The task was then to find the lightest possible structure which passes all of my failure tests. To do this, a genetic optimizer was employed, however it was eventually determined that the algorithm converged far too slowly in the highly discontinuous design space. Finally, a gradient based optimizer was used to optimize the continuous portion of the design space. It converged every time and ran ~100x faster than the genetic optimizer which was well worth it even though it meant I had to optimize the discontinuous variables by hand. After many design tweaks and 240 optimizations, the finalized structure was arrived upon. It can be seen in the image just above as well as in the 3D model seen below.

Designing this structure has been quite an epic adventure and resulted in an very lightweight structure which is below our estimated weight upon starting the project. I’m very excited to see how it will perform during flight!

Final Configuration of the Atlas quad structure.

The structure has required several new mandrels which have been fabricated, 3 of which are tapered. We are now into full production of the structure and aim to be complete in the coming weeks!